Healthcare

We have equipment for various purposes such as cultivation, inspection, drug formulation, filling, and state-of-the-art packaging, utilizing a lot of experience and an extensive know-how in medicine, food, cosmetics, and oil-related fields. In addition, we provide value-added products, these have won firm confidence from our customers.

Tablet / Capsule Visual Inspection System

More than 1,000 units of the advanced visual inspection systems for pharmaceutical industry manufactured by our affiliate Daiichi Jitsugyo Viswill has been sold, making it a market leading product.

Viswill original 3D inspection and image processing technology, stable transfer system and all other unique technologies enable us to be No.1 market share in the world of pharmaceutical visual inspection systems.

Viswill original 3D inspection and image processing technology, stable transfer system and all other unique technologies enable us to be No.1 market share in the world of pharmaceutical visual inspection systems.

Encapsuling and related machines

Suited to integrated production lines for capsules. We provide comprehensive solutions, including design of entire production lines and GMP compliance.

Our line-up starts from capsule filling machines which offer several types of filling method according to drug nature, hard gelatin capsule sealing machine and checkweighers, to ensure producing high quality products.

Our line-up starts from capsule filling machines which offer several types of filling method according to drug nature, hard gelatin capsule sealing machine and checkweighers, to ensure producing high quality products.

Color / Vacuum suction / Electrostatic Sorters

These sorters are designed for pharmaceutical processing, food processing, tea processing, medical processing and other industrial purposes.

Based on the great deal of experiences and extensive installation history, we choose the best method to various kinds of materials and products to be sorted accurately and efficiently by our machines.

Once a product sample is provided, we conduct evaluation test to find out which method is suitable, how accurate it is, and how much the processing speed is.

Based on the great deal of experiences and extensive installation history, we choose the best method to various kinds of materials and products to be sorted accurately and efficiently by our machines.

Once a product sample is provided, we conduct evaluation test to find out which method is suitable, how accurate it is, and how much the processing speed is.

Antiviral Filter Virus Guard

Antiviral Filter “Virus Guard” is the air filter with antiviral agent attached to the filtration materials.

By simply replacing the existing filter with the "Virus Guard", an antiviral effect can be obtained, so it can be used not only in hospitals, medical facilities, and factories, but also in shopping malls, office buildings, and public transportation to protect people from viruses.

It have been confirmed that this filter is effective in reducing 99.9987% of the COVID-19 virus (SARS-CoV-2) in just one hour.

By simply replacing the existing filter with the "Virus Guard", an antiviral effect can be obtained, so it can be used not only in hospitals, medical facilities, and factories, but also in shopping malls, office buildings, and public transportation to protect people from viruses.

It have been confirmed that this filter is effective in reducing 99.9987% of the COVID-19 virus (SARS-CoV-2) in just one hour.

Granular Inspection System

Granular inspection system accurately detects and removes foreign materials contaminated in granules and powder. Stable detection of not only black foreign materials and hairs, but also fine light colored foreign materials and discolored foreign matter.

It has a maximum throughput of 150kg/h, a maximum detection accuracy of 50μm, as well as easy maintenance.

The system helps to improve the efficiency of inspection of granules and powders and to improve safety and quality control for customers’ productions.

It has a maximum throughput of 150kg/h, a maximum detection accuracy of 50μm, as well as easy maintenance.

The system helps to improve the efficiency of inspection of granules and powders and to improve safety and quality control for customers’ productions.

Semi-Automatic Vial Inspection Machines

This Semi-Automatic Vial Inspection Machine can change the angle of vials transported by conveyor as suitable for defects to be inspected.

The angle can be designed from 60° to -45°.

Defects which can be inspected are cap and seal, crimp, rubber stopper, top/side/bottom of cake, etc.

Please contact us for more details.

The angle can be designed from 60° to -45°.

Defects which can be inspected are cap and seal, crimp, rubber stopper, top/side/bottom of cake, etc.

Please contact us for more details.

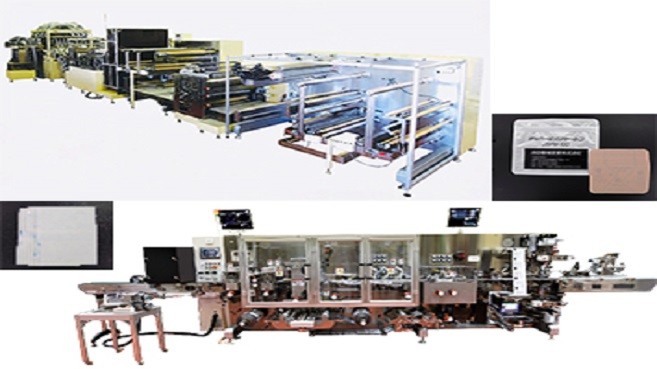

Patches and medical adhesive tapes manufacturing machines

Manufacturing machines for various types of medicals tapes such as first-aid adhesive bandages, patches, plasters, and transdermal drugs.

We have a great number of experience in the installation of integrated production lines that handle everything from ointment applying to inspection and packaging.

We can design machines and lines to meet your products and special requirements.

Please contact us for more details.

We have a great number of experience in the installation of integrated production lines that handle everything from ointment applying to inspection and packaging.

We can design machines and lines to meet your products and special requirements.

Please contact us for more details.

Auger-type Powder Filling Machines

The machine manufacturing is based on more than 50 years of experience and can be used for all kinds of powders.

The filling volume range is significantly wide as from 10mg to 30kg, and the filling container can be any kind of container such as paper bag and plastic bottle, as well as vial, ampoule, double bag, drum, etc.

We can also handle special specifications such as the filling of fine powders and aseptic filling.

Please contact us for more details.

The filling volume range is significantly wide as from 10mg to 30kg, and the filling container can be any kind of container such as paper bag and plastic bottle, as well as vial, ampoule, double bag, drum, etc.

We can also handle special specifications such as the filling of fine powders and aseptic filling.

Please contact us for more details.

PTP Blister Packaging Lines

We sell a PTP blister packaging line which realizes flat panel consecutive molding, which was not realized in the past. Therefore, we can give solutions to customers employing conventional flat panel intermittent molding.

We also sell a 4 direction-sealed packaging line which enables all sheet gauges by weight checkers and automatically adjustable mass measuring with the cutting margin of packaging material being as little as possible, utilizing a patented technology called film constant tension systems. In addition, we recommend a high-speed packaging line which realizes 2,000 packagings (6 rows) per minute which is the world’s fastest packaging speed.

We also sell a 4 direction-sealed packaging line which enables all sheet gauges by weight checkers and automatically adjustable mass measuring with the cutting margin of packaging material being as little as possible, utilizing a patented technology called film constant tension systems. In addition, we recommend a high-speed packaging line which realizes 2,000 packagings (6 rows) per minute which is the world’s fastest packaging speed.